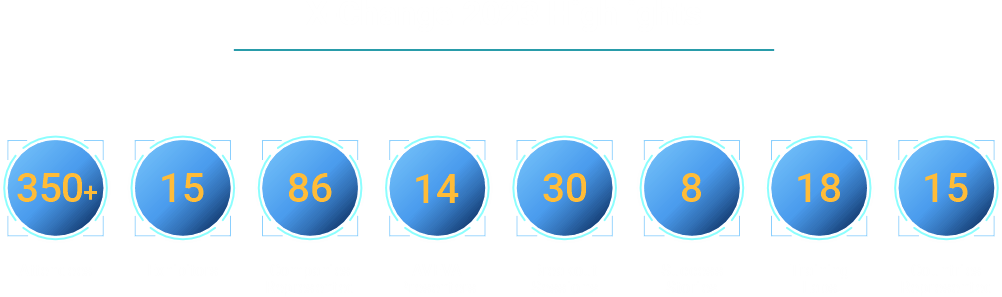

X-Change is an annual gathering of tech enthusiasts, industry leaders, and visionaries pushing the boundaries of innovation. Join us for an immersive experience that celebrates the latest in technology, fosters networking opportunities, and discover how your organization can benefit from AVEVA software and our industry solution partner ecosystem.

Be part of this year’s commemorative milestone of connecting industries for the last three decades.

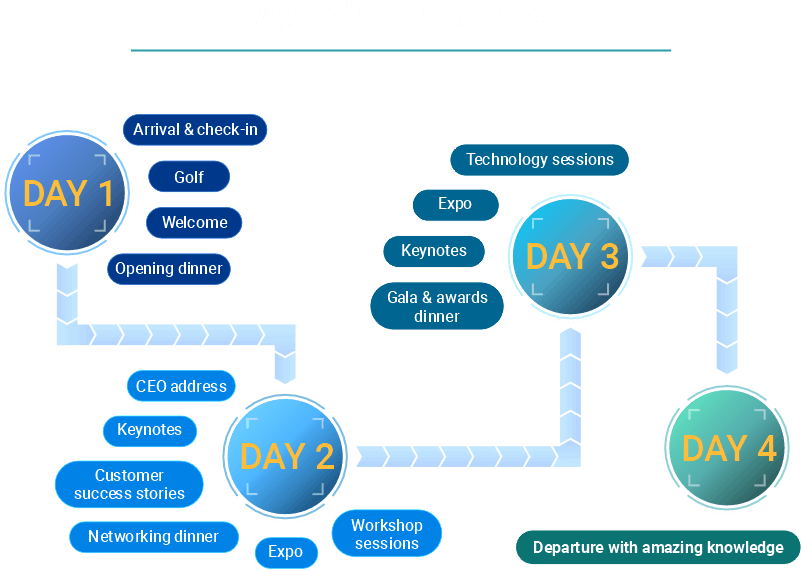

Date: 9 – 12 June 2024

Location: Champagne Sports Resort, Drakensburg

Throughout these three decades, we’ve not only adapted but thrived. We’ve embraced change, conquered challenges, and revolutionized the way the world operates. Our journey has been marked by countless success stories, partnerships, and friendships, and we look forward to celebrating these achievements with all of you.

Hear what our community has to say about what to expect at X-Change.

Bring Your Whole Team

This conference is an excellent opportunity for you and your team to hear directly from proven business leaders, technology experts and your peers to learn how they are using digital solutions to improve efficiency, cut costs and drive profitability. Interested in attending but need help communicating the value of the X-Change User Conference, South Africa? Use our justification letter template designed to help your employer understand the benefits of attending this conference.

Have any questions?

Please contact Neetu Michael on +27 87 405 8413

or Megan Nitsche on +27 83 287 5420

Alternatively, email: x-change@thundervent.co.za

Location & travel considerations:

Recommended route:

Please ensure that you review the recommended route

to ensure that you avoid the temporary road closure.

Location URL:

Google maps link

Directional assistance:

Champagne Sports Resort reception (+27 36 468 8000)

Venue’s website:

https://www.champagnesportsresort.com

Resort map:

The champagne sports resort map can be found on

the X-Change website along with other resources.

Don’t miss out – come make a difference as a Digital Champion!

Hosted by Africa’s leader in industrial software innovation

– an AVEVA Select partner –